About

Software Engineer in Goleta California. I earned a B.S. in Computer and Electrical Engineering at UC Davis in 2019. In fall of 2021, I will be starting my Master's in Computer Science program at Georgia Institute of Technology with an emphasis in Machine Learning. I currently work as full-time Software Engineer at Raytheon Technologies in Goleta, California.

Software Engineer

- Phone - (530) 526 7512

- Email - williamharrisgentry@gmail.com

- City - Santa Barbara, CA

- B.S. - Electrical and Computer Engineering

- M.S. - Computer Science (in progress)

Software Engineer with broad experience in developing embedded systems and desktop applications. Proficient at the visualization of complex software architecture concepts and skilled at implementation. In-depth understanding of computer architecture and high-level object-oriented design. Strong problem-solving abilities assisted by attention to detail and quickly identifying root cause.

Skills

Resume

Education

Master of Science in Computer Science

2021 - Present

Georgia Institute of Technology, Atlanta, GA

Emphasis in Machine Learning

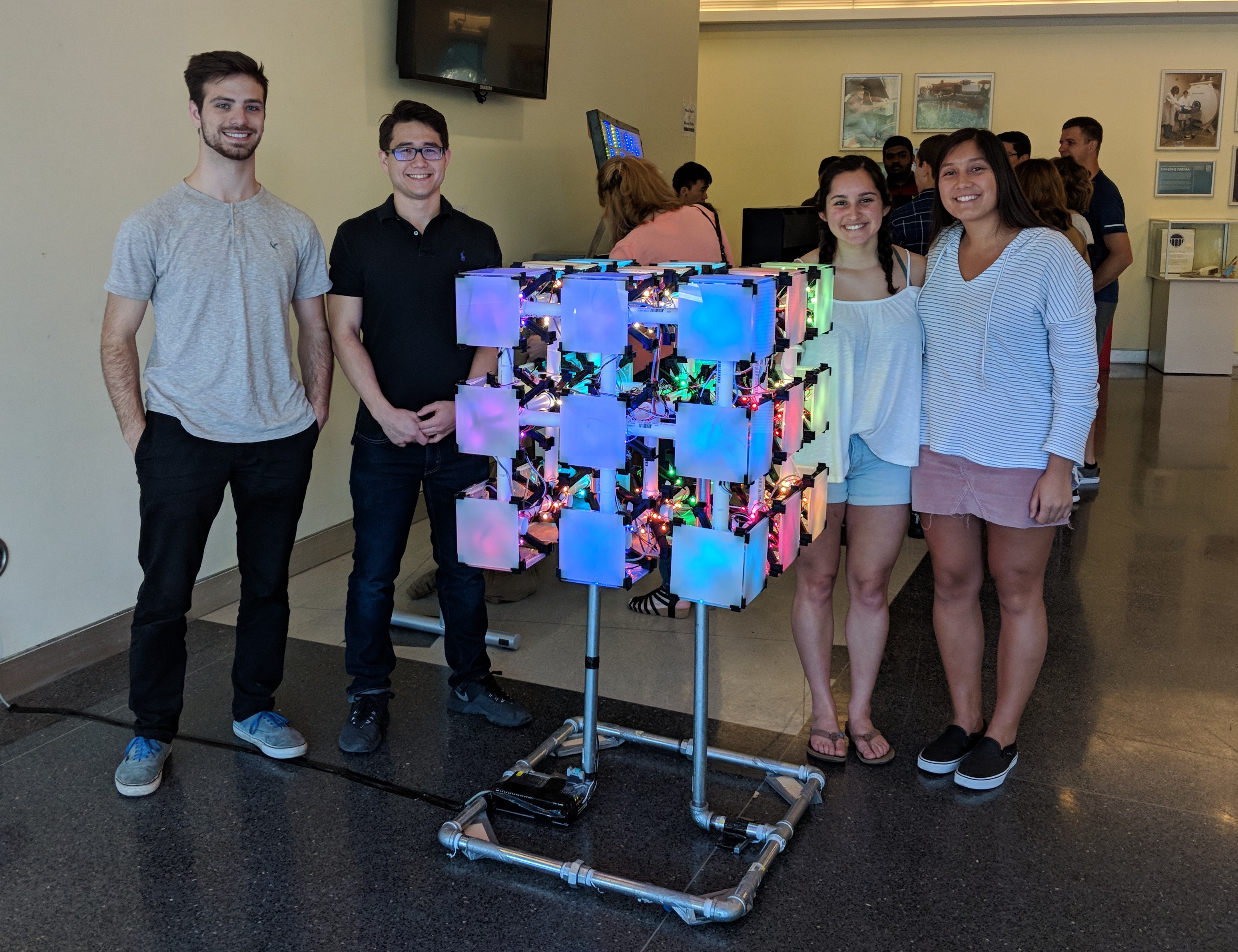

Bachelor of Science: Computer & Electrical Engineering

2015-2019

University of California, Davis

Minor in Technology Management

Professional Experience

Software Engineer

2020 - Present

Raytheon Technologies, Goleta, CA

- Created utility application to automate the installation of device drivers and configuration of the OS.

- Assisted in the development and testing of an automated serial programming system.

- Maintained commercial embedded system and instrumentation software for radar related systems written in Ada and C++.

- Designed and developed .NET Core WPF C# desktop application for data visualization of complex antenna characteristics.

- Effectively communicated in cross-functional teams composed of system and electrical engineers.

Controls Execution Intern

2019

General Motors, Detroit, MI

- Collaborated with process engineers in powertrain manufacturing engineering to retool assembly and test equipment.

- Implemented process improvements for increased efficiency and quality.

- Enabled automated tracking and tracing of product assembly by creating data records and Allen-Bradley PLC control logic.